MelonKote850 a coating for the protection of steel parts; during austenitizing; against decarburization and oxidation.

While heating (austenitizing) before hardening steel is so hot that it even glows. Austenitizing temperature reaches over 750 degrees (Celsius).

At this temperature (and above) steel (and the coal contained in it) reacts with components of the atmosphere (oxygen, carbon dioxide, water vapor) and forms scalings on the surfaces, while reducing the amount of carbon in the steel.

The oxidation of the steel is very visible (creates scalings) and disliked for example by the blacksmiths. Steel „disappears” in the eyes, reduce its amount, it forms a hard, visible mill scale.

The loss of carbon during heating is called decarburization, but here you can not see the loss of carbon. Therefore this phenomenon is more dangerous than the oxidation (visible to the human eye, easy to remove in 100%). Thus, in steel with a carbon content of 1% after austenitising the amount of carbon on the surface can be reduced to approx. 0.5% C. Thus, the „core” of steel is correct, the surface is not as hard as the technology requires, the part is more liable to cracking. The tensile stresses, which appear on the surface of the decabonized part, are at fault.

In the industry there are used: vacuum furnaces, furnaces with an active atmosphere, or with the atmosphere created with noble gases. This is to protect steel parts just before decarburization.

In the electric chamber furnaces such a protection does not exist.

Although not, IT DOES EXIST. The foil inox for hardening can be used. The ideal solution, cheap and easy. But it has a disadvantage: it can be used to protect against decarburization only a regular and high-alloy steel (class of 1.2363 / A2, D2 / K110, N690) having a minimum chromium content approx. 4%. Steels with lower chromium will not be tempered if we’ll use the foil inox for tempering.

The panacea for this could be a coating that protects against decarburization (while also against decarburization), which I allowed myself to develop and place on the market.

MelonKote850 coating is designed to protect non-alloy steel (class 1095 with profile-sections up to 6 mm) and low alloy steels (class of 52100, O1, 1.2550 with sections up to 8-10mm). Protecting against decarburization during austenitizing at the same time, slightly reduces the cooling rate during tempering. Despite a decrease in the cooling speed, steel parts will be tempered correctly.

It is purposed for use in temperatures up to 850st. C and in time -one hour. BUT it can also be used to protect steel 1.2550 (austenitizing temperature: 880-920 deg. C) with a satisfactory results.

MelonKote850 coating slightly reduces the speed of cooling. If the parts after hardening did not show a satisfactory hardness, usually it is enough to raise the temperature of austenizing by 10st. C and the parts will reach the proper hardness.

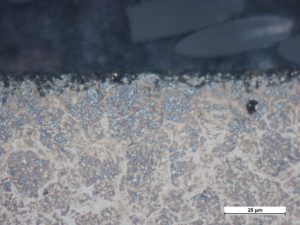

Steel with a properly applied MelonKote850 coating (when dry):

Parts after austenitizing and tempering.

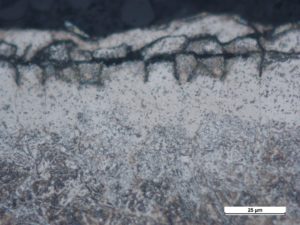

Parts after austenitizing and tempering.

Strikeout = PROTECTED WITH MELONKOTE850

Update 2017 08

Parameters:

Steel 52100, fi 20mm, thickness 10mm, sanded with paper # 500

Coat applied with a brush, after 2h the second layer, – into the oven after 24h from the application of 1 layer.

Austenitization: Temperature / Time 900 ° C / 1h

Hardening in 50 ° C oil

Protected steel MelonKote850. Hardness HRC: 63, 63, 64, 64, 64. A few μm at the surface showed something oxidized (Flamberg’s conclusion)

Steel without protection. Hardness HRC: 56, 54, 55, 56, 59 (very thick oxide layer).

Thank you to all who helped me to work on MelonKote850: Kolec7, BrrKnives Flamberg, Graf, Rumcajs, Lola, Lilu, Junior and others I forgot to mention here.

Sale: https://enigma24.eu/pl/p/-MelonKote850-powloka-przeciw-odwegleniom/174

Safety Data Sheet:

http://blog.melontools.com/foty/knives/Safety_Data_Sheet_Melonkote850.pdf

http://blog.melontools.com/foty/knives/KARTA_CHARAKTERYSTYKI_MELONKOTE850.pdf

Instrukcja stosowania/instructions for use:

http://blog.melontools.com/foty/knives/MELONKOTE850_instruction-instrukcja.pdf